Description

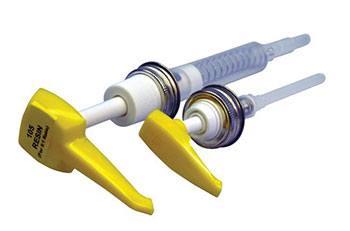

Junior Pack West System

105 Epoxy Resin is the base material on which all West System 105 System epoxy compounds are built. The resin is a clear, pale yellow, low-viscosity liquid epoxy resin. Formulated for use with West System hardeners, it can be cured in a wide temperature range to form a high-strength solid with excellent moisture resistance.

105 Resin is formulated without volatile solvents and does not shrink after curing. It has a relatively high flash point and no strong solvent odor, making it safer to work with than polyester or vinylester resins. Resin viscosity is approximately 1000 centipoise (cp) at 72°F (22°C).

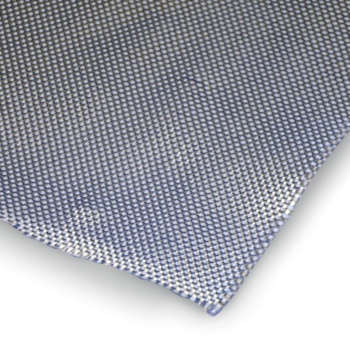

105 Resin is designed specifically to wet out and bond with wood fiber, fiberglass, reinforcing fabrics and a variety of metals when mixed at the proper ratio with a West System hardener. An excellent adhesive, 105 mixtures will bridge gaps and fill voids when modified with West System fillers and can be sanded and shaped when cured. With roller applications, it has excellent thin-film characteristics to flow out and self-level without fisheyeing. 105 Resin/207 Hardener mixtures cure clear so you can achieve a natural finish when coating with varnish.

205 Fast Hardener is a medium-viscosity epoxy curing agent. It is used in a majority of situations, at lower temperatures and to produce a rapid cure that develops its physical properties quickly at room temperature. When mixed with the 105 Resin in a five-part resin to one-part hardener ratio, the cured resin/hardener mixture yields a rigid, high-strength, moisture-resistant solid with excellent bonding and coating properties. Not intended for clear coating.

- Pot Life at 72F (22C): 9 to 12 minutes

- Cure to a solid state: 6 to 8 hours

- Cure to maximum strength: 1 to 4 days

- Minimum recommended temperature: 40°F (4°C)

- Pack contains: 0.5Kg 105 Resin, 0.1Kg 205 Hardener